Industrial Drying Equipment

Vertical Ribbon Vacuum Dryer

Industrial Drying Equipment

Vertical Ribbon Vacuum Dryer

- Inner diameter 500-2300mm

- Power 1.5-22kW

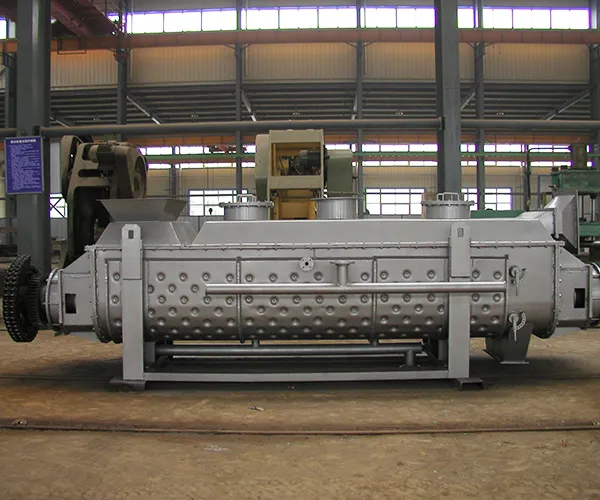

The vertical ribbon vacuum dryer is a conductive vacuum drying system designed for efficient, low-temperature drying of moisture-sensitive materials. It operates in batch mode with a jacketed vessel, allowing for precise thermal control.

Material is fed from the top of the dryer and continuously agitated by a helical ribbon stirrer, ensuring uniform mixing and direct contact with the heated surfaces. Heat transfer media such as steam, hot water, thermal oil, or molten salt can circulate through the jacket, main shaft, and ribbon blades, maximizing heat distribution throughout the product.

Moisture released during drying is drawn out through a vacuum port at the top and removed by a vacuum pump. Once the drying process is complete, the dried material is discharged through an outlet at the bottom of the vessel.

- Available in a wide capacity range from 50L to 30,000L, this closed system uses conduction drying under vacuum conditions, achieving pressures below 1 mbar. It supports operation temperatures up to 200°C, with an internal mirror-polished surface (Ra ≤ 0.6 μm) for optimal cleanliness and product handling.

- Operates in batch mode, eliminating the risk of cross-contamination between products. Its sanitary design complies with GMP and FDA standards, making it suitable for applications in pharmaceuticals, food, and high-purity chemicals.

- The material is continuously and uniformly agitated during the drying process, ensuring effective heat transfer without buildup, scaling, or the formation of sticky clumps, common issues often described as the "snowball effect."

- Chemical industry

Suitable for drying chemical raw materials such as potassium chloride, ammonium chloride, ammonium sulfate, and similar compounds. - Pharmaceutical industry

Ideal for drying a wide range of herbal extracts, medicinal ingredients, and pharmaceutical intermediates under controlled, contamination-free conditions. - Food industry

Used for drying various food ingredients including protein powders, yeast powders, and fish meal, especially when low-temperature vacuum drying is required to preserve product quality.