Company

Company Name

Hebei Yanming Chemical Equipment Co., Ltd.

Company Abbreviation

Hebei Yanming

Value

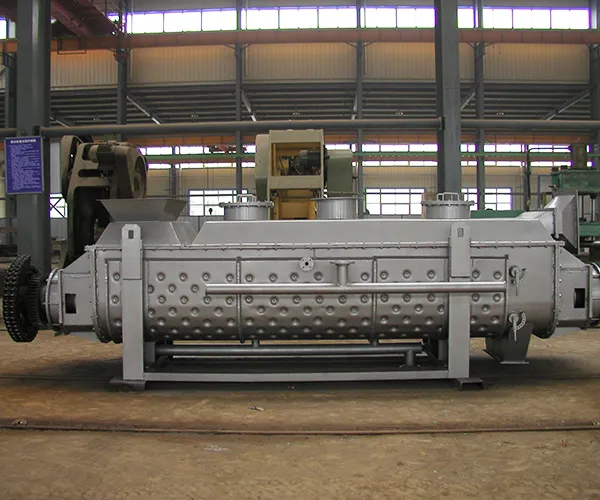

Process equipment manufacturer specializing in drying, evaporation, crystallization, and filtration for lithium battery materials, chemicals, pharmaceuticals, and food industries.

Main Business

Dryers, evaporators, cooling crystallizers, filtration systems, turnkey process solutions

Certificates & Honors

ISO 9001, ISO 14001, ISO 45001

Contact

No. 155 Kuanting Street, Circular Chemical Industrial Park, Shijiazhuang City, Hebei Province

chemsystem-en.com

13933883976@163.com