Industrial Filtration Equipment

Agitated Nutsche Filter Dryer

Used for solid-liquid separation, solids washing and drying

Industrial Filtration Equipment

Agitated Nutsche Filter Dryer

Used for solid-liquid separation, solids washing and drying

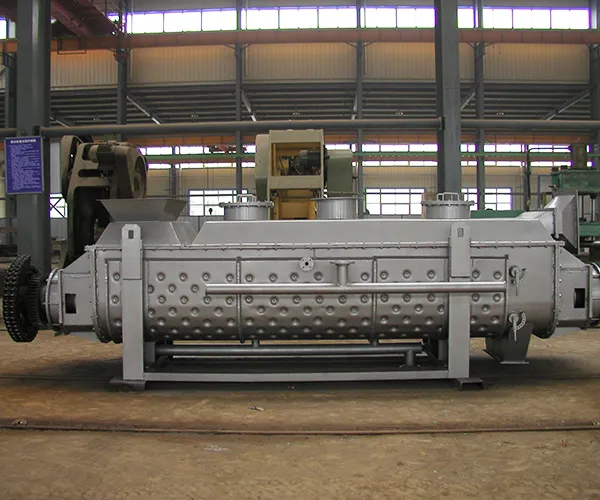

The agitated Nutsche filter dryer is an integrated solid-liquid separation system that combines filtration, washing, drying, and solid discharge in a single, fully enclosed unit. It enables a continuous, contained process making it ideal for handling toxic, sensitive, or sterile materials.

Designed for efficiency and safety, this three-in-one solution eliminates the need for multiple transfers between equipment, reducing contamination risk and improving operational control. It is especially well-suited for pharmaceuticals, fine chemicals, agrochemicals, and other applications requiring GMP compliance, solvent recovery, and cleanroom integration.

- Pharmaceutical industry

Used for solid-liquid separation, washing, drying, and discharge of active pharmaceutical ingredients (APIs). It is ideal for handling sensitive, high-value, sterile, or environmentally hazardous materials under strict containment. - Chemical industry

Widely applied in the processing of various complex or hazardous compounds, including materials that require controlled drying and closed-system handling to maintain product purity and operator safety. - Agrochemical industry

Used for processing crystal-containing materials in pesticide production, helping to reduce transfer steps and improve processing efficiency. - Food processing

Applied in the treatment of food ingredients where post-filtration impurity removal and drying are critical to ensuring product texture, stability, and shelf life.