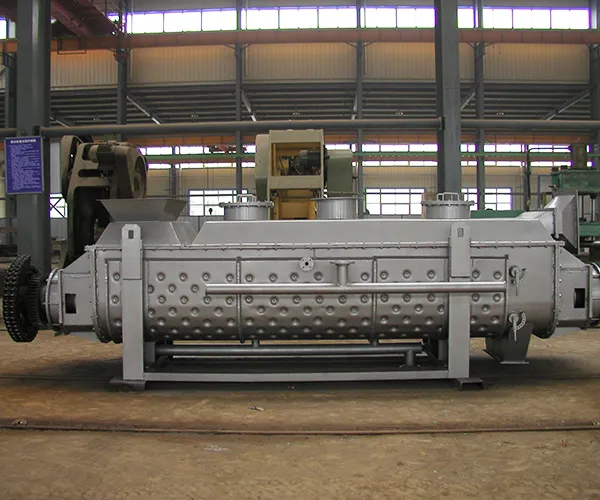

Industrial Drying Equipment

Fluid Bed Dryer

Industrial Drying Equipment

Fluid Bed Dryer

- Fluid bed size (L×W) 8000×1500mm

- Vibration motor power 5.5×2kW

The fluid bed dryer applies mechanical vibration to a conventional fluidized bed system, improving material movement and heat exchange efficiency. Under the combined action of vibration and airflow, the material enters a fluidized state and moves continuously along the bed.

As hot air passes through a perforated distribution plate, it makes direct contact with the material, facilitating effective heat and mass transfer. By adjusting vibration parameters, the drying system can achieve a more uniform plug flow, overcoming the back-mixing typically seen in standard fluidized beds during continuous operation.

- Equipped with a vibration motor, the drying system reduces the minimum fluidization velocity, significantly lowering the volume of heated air required and minimizing dust entrainment. This also helps reduce the size and cost of supporting equipment.

- The fluidized state allows for full contact between material and hot air, ensuring uniform drying with a high heat transfer coefficient and notable energy savings.

- Offers excellent process flexibility, allowing the residence time to be adjusted based on material characteristics for optimal drying performance.

Fluid bed dryers are widely used for drying chemical raw materials and finished products, pharmaceutical powders, as well as food additives and flavoring agents. Their efficient heat and mass transfer capability makes it suitable for a broad range of temperature-sensitive and particulate materials.