Industrial Evaporation Equipment

Wiped Film Evaporator

Industrial Evaporation Equipment

Wiped Film Evaporator

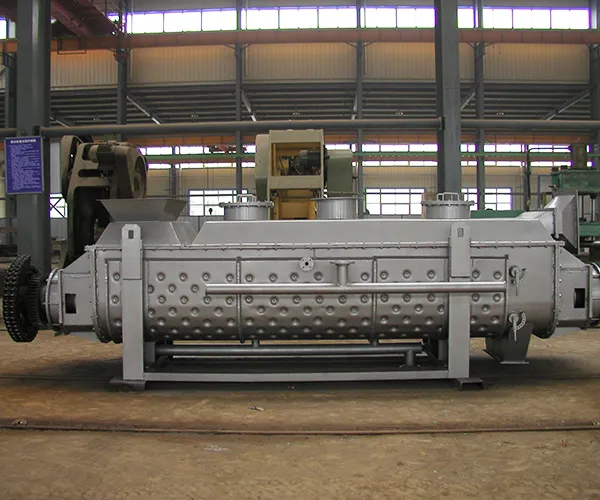

The wiped film evaporator is a highly efficient thermal separation equipment designed to continuously separate volatile compounds, that uses high-speed rotating blades to continuously distribute liquid into a uniform thin film along the inner wall of a heated cylinder. This design enables rapid evaporation or distillation, even for heat-sensitive, viscous, or fouling-prone materials. It operates under high vacuum in order to reduce operating temperatures for high boiling and heat sensitive products. In addition to evaporation, the thin film evaporator can also perform deodorization, degassing, heating, cooling, and other unit operations. Various blade configurations are available, including centrifugal, hinged, and fixed scraper types, to match specific process conditions and requirements.

- Chemical industry

Used for distillation, concentration, and solvent removal, especially with heat-sensitive or viscous materials. - Food industry

Applied in evaporation, solvent stripping, and drying processes. The evaporation system reduces thermal residence time, helping to prevent degradation or caramelization while preserving the original flavor and nutritional value of food ingredients. - Pharmaceutical industry

Used for extraction, concentration, and crystallization of pharmaceutical compounds. The short residence time and gentle evaporation conditions help maintain drug potency and active ingredients. - Environmental industry

Used in the treatment of industrial wastewater and off-gases, enabling the separation and concentration of harmful substances, and reducing the environmental impact of industrial waste.