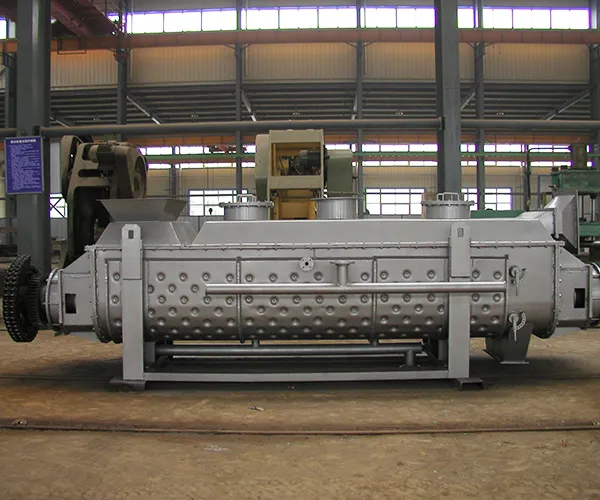

Industrial Evaporation Equipment

Natural Circulation Evaporator

Industrial Evaporation Equipment

Natural Circulation Evaporator

The natural circulation evaporator relies on density differences in the liquid to drive circulation, without the use of external pumps. The typical circulation velocity is less than 1 m/s, making it suitable for applications where gentle flow is sufficient. To prevent scaling and crystallization, the heating tubes must remain fully submerged during operation. This evaporator type is best suited for solutions with mild scaling tendencies and low corrosiveness. We offer multiple structural configurations such as coil-type, central circulation tube, and external heating-type evaporators, all of which can be customized to meet specific process requirements.

Natural circulation evaporators are widely used in chemical, pharmaceutical, food processing, and industrial wastewater recovery sectors. They are primarily applied for concentration, crystallization, separation, drying, and resource recovery of low-corrosive, moderately scaling liquids.

What is a natural circulation evaporator?

What are the key steps involved in its operation?

The evaporation process in a natural circulation system involves four main steps:

- Heat input to initiate evaporation

- Natural fluid circulation driven by density variation

- Vapor generation in the heating chamber

- Condensation of vapor in the condenser section