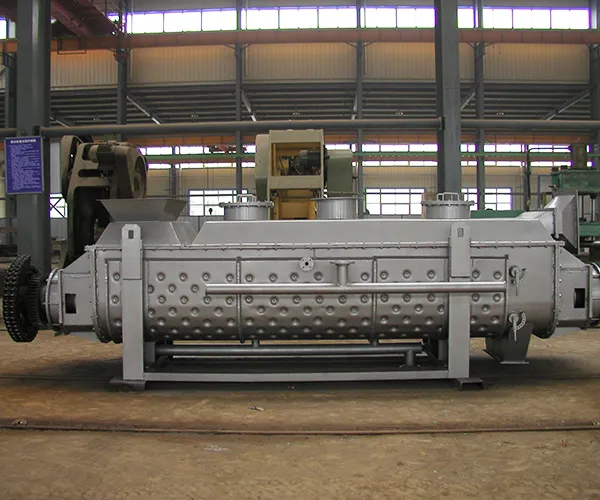

Industrial Crystallization Equipment

OSLO Crystallizer (Fluidized Bed Crystallizer)

Industrial Crystallization Equipment

OSLO Crystallizer (Fluidized Bed Crystallizer)

The OSLO crystallizer is a type of fluidized bed crystallization system designed for continuous operation, offering excellent control over crystal size and purity. It is available in evaporative and cooling configurations. The fluidized bed crystallizer is ideal for producing large, well-defined crystals, particularly in processes requiring low supersaturation and extended crystal residence time. OSLO crystallizers are commonly used in industries such as chemicals, fertilizers, pharmaceuticals, and resource recovery.

- Processing capacity: 0.5 – 50 tons per hour

- Material construction: Available in SUS304, 316L stainless steel, and titanium alloy

- Crystal size: Capable of producing crystals larger than 3.0 mm

All technical parameters can be customized based on specific process requirements.

Application

- Pharmaceutical manufacturing

Used to produce high-purity pharmaceutical crystals, ensuring uniform particle size and enhanced bioavailability. - Chemical synthesis

Applied in organic synthesis for the purification and separation of intermediate or final compounds with controlled crystallization conditions. - Fine chemicals

Ideal for manufacturing high-purity specialty chemicals, where precise control over crystal structure and purity is essential. - Food processing

Used in the production of food additives and flavor enhancers, offering consistent quality and particle uniformity. - Mineral extraction

Enables the separation and purification of valuable minerals during resource recovery and refining processes.

How does an OSLO crystallizer differ from traditional crystallizers?

How does an OSLO crystallizer differ from traditional crystallizers?

The OSLO crystallizer differs in structure, operating principle, product characteristics, and process advantages. Its fluidized bed design offers improved crystal growth control, reduced nucleation, and better separation of large crystals, making it particularly suitable for specialized crystallization applications.

How does material selection affect the performance of an OSLO crystallizer?

How does material selection affect the performance of an OSLO crystallizer?

The choice of materials directly impacts the crystallizer’s corrosion resistance, wear resistance, and thermal conductivity. Using appropriate materials ensures long-term reliability, improves energy efficiency, and supports product quality in demanding chemical environments.

Does operating under low temperatures affect performance?

Does operating under low temperatures affect performance?

No. OSLO crystallizers are well-suited for low-temperature (or cooling) crystallization processes. They are particularly effective for materials with high crystal density and low-viscosity mother liquors, maintaining stable operation even in chilled conditions.