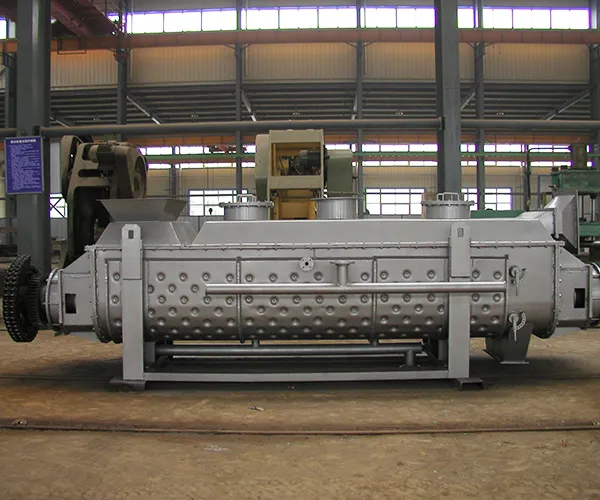

Industrial Crystallization Equipment

DTB Crystallizer (Draft Tube Baffle Crystallizer)

Industrial Crystallization Equipment

DTB Crystallizer (Draft Tube Baffle Crystallizer)

The DTB crystallizer is a high-efficiency crystallization system designed for evaporative crystallization from supersaturated solutions. It is suitable for processes with vacuum cooling and moderate evaporation rates and is widely used in chemical processing, metal smelting, acid recovery from steel pickling, and desulfurization wastewater treatment in power plants.

DBT crystallizers are typically PLC-controlled to precisely regulate material temperature, ensuring consistent nucleation and crystal growth. At the core of the DTB design is a vertical axial-flow circulation pump, characterized by large flow rates, low head, low speed, and a large-diameter impeller. The design and performance of this pump are critical in determining the final crystal size distribution. DTB crystallizers can be fully customized based on specific process and material requirements.

- Upward velocity in the draft tube: ≤ 1 m/s

- Settling velocity in the vapor separation chamber: ≤ 0.2 m/s

- Settling velocity in the crystallization zone: ≤ 0.1 m/s

- Settling velocity in the mother liquor zone: ≤ 0.05 m/s

- Chemical industry

Widely used for the crystallization of products such as ammonium chloride, potassium nitrate, and hydroquinone, where precise crystal size control and purity are essential. - Pharmaceutical industry

Ideal for pharmaceutical manufacturing due to its hygienic design, automated control, and high product purity, making it critical in the production of active pharmaceutical ingredients (APIs). - Agrochemical industry

Used for crystallizing pesticide compounds, improving both product quality and production efficiency through consistent crystal formation and effective impurity removal.