- The drying system operates continuously and achieves thermal efficiency above 85%, making it suitable for stable, high-volume production.

- Each drying tray can be individually connected to a heating or cooling medium. This setup allows drying in the upper section and cooling in the lower section, with accurate and consistent temperature control throughout the process.

- Drying and cooling zones are separated within the same unit to prevent moisture from the drying area from reaching the cooling zone. A designated opening ensures material flow while avoiding condensation that could raise the final moisture level.

- Sodium sulfate tends to form crusts during drying. To prevent this, a custom rake arm and rake balde structure is used to minimize material buildup on the tray surface and maintain consistent product flow.

- For high-capacity rotary tray dryers, internal adjustments are made to prevent wet material from falling directly onto the base of the unit, which could result in uneven final moisture content.

- To avoid damage to threaded connections on the rake arms in high-throughput drying systems, a removable installation structure is used. This makes maintenance easier and reduces wear during continuous operation.

- A material leveling device is installed at the top of the dryer to ensure even product distribution across the trays. This prevents material from falling directly onto the trays from the feeder, which could damage the rake arms or affect drying uniformity.

-

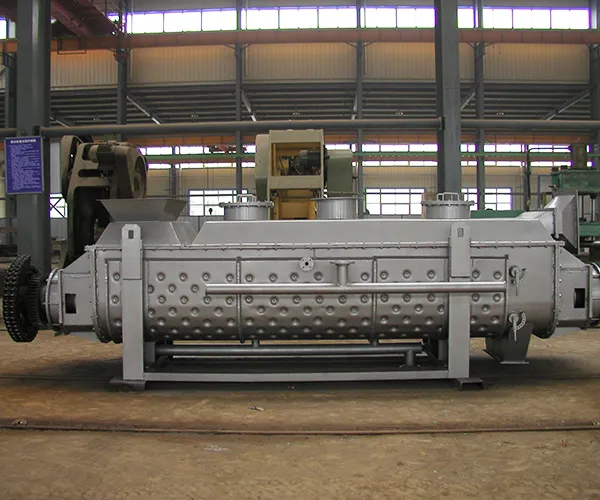

- Rotary Tray Dryer

- Drying area 3.3-168m²

- Power 1.1-18.5kW