Industrial Drying Solutions

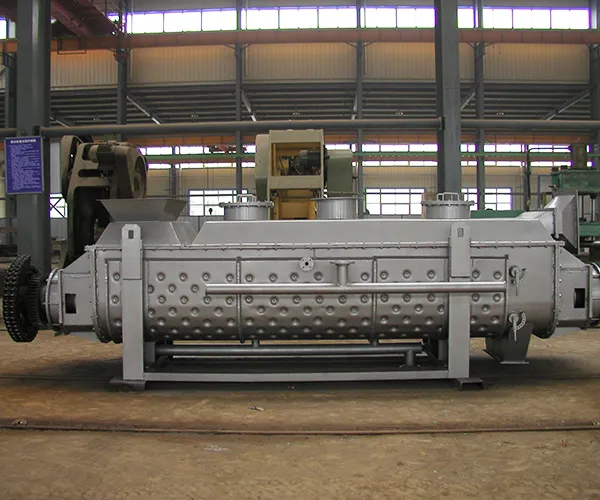

Ternary Material and Precursor Drying System

We provide industrial drying solutions for ternary materials composed of nickel, cobalt and manganese in lithium ion batteries

Material Characteristics

Ternary materials such as lithium nickel cobalt manganese oxide (Li(NiCoMn)O₂) are commonly used in lithium-ion batteries for electric vehicles. The precursor, spherical nickel hydroxide (also referred to as spherical nickel), typically has a loose, powdery or slightly lumpy texture. It has limited flowability and a blue-green appearance. Moisture content before drying usually ranges from 10% to 15%, depending on the raw materials and process, and must be reduced to between 0.5% and 1.0% to meet product quality standards.

Specialized Drying Process

Drying Conditions and Considerations for Ternary Materials and Precursors

Ternary materials and their precursors, such as spherical nickel hydroxide, have a loose texture and generally acceptable flowability. The drying process must ensure low energy consumption, uniform heat distribution, and a clean working environment. Product quality targets should be achieved in a single pass to maintain process efficiency. For battery-grade applications, magnetic contamination introduced during drying must be kept below 20 ppb. Due to the fine particle size, dust collection is challenging and requires a reliable recovery system.