-

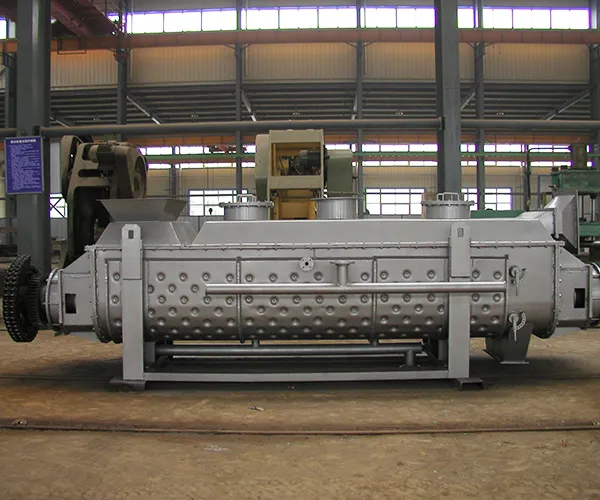

- MVR Evaporator

- Evaporation capacity 500kg/h-60t/h

- Evaporation temperature 40-100℃

Turnkey Process Equipment Solutions

Conversion of Li₂SO₄ Solution into Battery Grade LiOH

We provide complete process system for the production of battery-grade lithium hydroxide

Turnkey Process Equipment Solutions

Conversion of Li₂SO₄ Solution into Battery Grade LiOH

We provide complete process system for the production of battery-grade lithium hydroxide

To produce battery-grade lithium hydroxide from a purified lithium sulfate solution, the liquid is first treated with chelating resin to remove calcium. It is then blended with a sodium hydroxide solution in precise proportions to form a feed solution. This mixture undergoes a cooling crystallization stage to precipitate sodium sulfate decahydrate (mirabilite), followed by centrifugation to separate the lithium hydroxide solution.

The lithium-rich solution is processed through a first evaporation and crystallization step to obtain lithium hydroxide monohydrate. The resulting crystals are redissolved in pure water, then passed through a second evaporation and crystallization stage to ensure higher purity. Afterward, the product is dried, sieved, demagnetized, milled, blended, and packaged to meet battery-grade quality standards. The sodium sulfate byproduct recovered during the cooling crystallization is further processed through redissolution and evaporation to obtain anhydrous sodium sulfate, ensuring efficient resource use throughout the chemical processing system.

From dryers and evaporators to crystallizers and turnkey systems, our team is ready to help you move forward with the right solution.

- Email: 13933883976@163.com