- The first stage washing liquid recovered from the second centrifugation can be recycled to the sodium carbonate dissolution step for reuse.

- The mother liquor separated during the first centrifugation may be processed through acid treatment and evaporation crystallization to produce anhydrous sodium sulfate.

- Producing battery-grade lithium carbonate from purified lithium sulfate solution can also involve methods such as causticization with sodium hydroxide, cooling crystallization, evaporation crystallization, re-dissolution, and carbonation using CO₂.

Turnkey Process Equipment Solutions

Conversion of Li₂SO₄ Solution into Battery Grade Li₂CO₃

We provide complete process system for the production of lithium carbonate slurry used in battery manufacturing

Turnkey Process Equipment Solutions

Conversion of Li₂SO₄ Solution into Battery Grade Li₂CO₃

We provide complete process system for the production of lithium carbonate slurry used in battery manufacturing

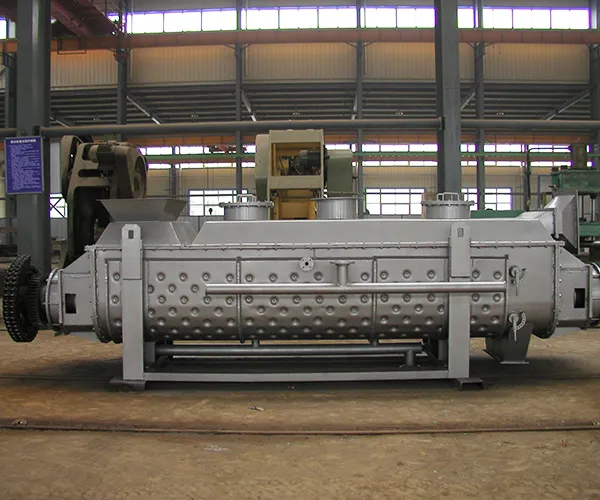

After calcium removal through chelating resin and other purification steps, the lithium sulfate solution reacts with a prepared sodium carbonate solution in a lithium precipitation tank under controlled temperature. This reaction forms a lithium carbonate slurry rich in sodium sulfate. The slurry undergoes the first stage of centrifugal separation to yield crude lithium carbonate, which is then transferred to a first-stage washing tank. There, it is mixed with a pre-measured volume of second-stage washing liquid. The resulting slurry proceeds to a second centrifugation step to obtain partially purified lithium carbonate.

Next, the material enters a second washing tank, where it is mixed with pure water to remove remaining impurities. The resulting slurry then undergoes a third centrifugation to isolate the purified lithium carbonate. Final processing includes drying, sieving, iron removal, milling, blending, and packaging to produce battery-grade Li₂CO₃.

From dryers and evaporators to crystallizers and turnkey systems, our team is ready to help you move forward with the right solution.

- Email: 13933883976@163.com