Process Equipment

Industrial Evaporation & Crystallization Solutions

Lithium Carbonate Carbonation System

We provide Li₂CO₃ carbonation solutions for producing high purity lithium carbonate used in battery manufacturing

Industrial Evaporation & Crystallization Solutions

Lithium Carbonate Carbonation System

We provide Li₂CO₃ carbonation solutions for producing high purity lithium carbonate used in battery manufacturing

High-purity lithium carbonate is widely used in the production of advanced cathode materials for lithium-ion batteries, as well as in the preparation of battery-grade lithium fluoride. In the optoelectronic field, it serves as a key raw material for producing lithium tantalate and lithium niobate. It’s also applied in specialty optical glass, magnetic materials, supercapacitors, and pharmaceutical products.

Process Overview

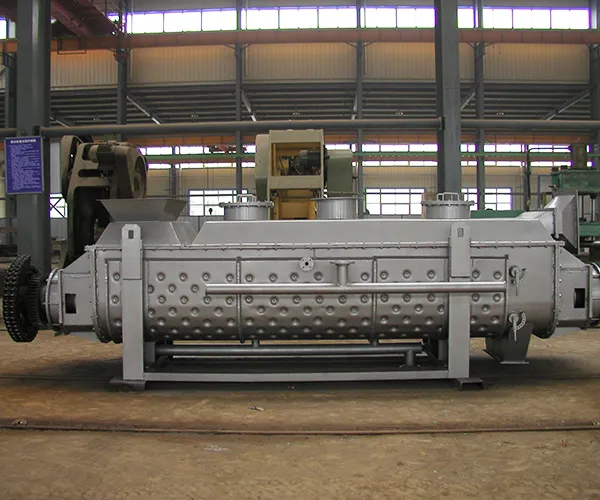

Carbonate slurry is prepared by blending lithium carbonate with pure water and recycled mother liquor in a precise ratio. This mixture is pumped into the carbonation tower, where carbon dioxide gas is introduced under controlled pressure and temperature, resulting in the formation of lithium bicarbonate solution. The carbonated solution is filtered through a filter press and a precision filtration unit, then passes through a resin column for impurity removal. It subsequently flows into a continuous decomposition tower for further processing. The decomposed solution undergoes centrifugal separation to isolate solids. The wet material is then dried, screened, demagnetized, crushed, and packed to yield high-purity lithium carbonate. Part of the decomposed mother liquor is returned to the slurry preparation system, while the remainder is handled separately. The CO₂ generated during decomposition can be recovered, depending on market conditions.

Features

- Operates continuously with advanced automation that reduces manual intervention.

- Maintains stable lithium carbonate quality with a consistently high yield.

- The countercurrent flow between the material and CO₂ stream maximizes gas utilization and overall process efficiency.

- Designed to minimize scaling, allowing for longer uninterrupted operation.

- Achieves high conversion rates of lithium carbonate with minimal material loss.

- Low lithium concentration in the residual solution ensures high recovery efficiency.

- Compact and space-saving layout, designed for easy and straightforward operation.

Looking for the right process equipment?

From dryers and evaporators to crystallizers and turnkey systems, our team is ready to help you move forward with the right solution.

- Email: 13933883976@163.com

Process Equipment